Local Motors’ Mitch Menaker on open-source innovation and the power of ideas

Built on an open-source co-creation community and microfactories, Local Motors is a company of firsts. It was first to crowdsource a complete car. Then it created the world’s first 3D printed car, using the Chicago 2014 car show to print, assemble and drive it away. We talk to Local Motors’ Chief Sales Officer Mitch Menaker about micro-manufacturing, innovation and how to develop an open platform to adapt to whatever the future brings.

In a nutshell, tell me about Local Motors.

Local Motors is a technology company that designs, builds and sells vehicles. Our brand message revolves around the 3 S’s – everything we do is Safe, Smart, and Sustainable.

Tell me more about your microfactories and how they relate to Local Motors’ retailing.

Our microfactories have four distinct components. The first component is our 3D printing and assembly area consisting of approximately 5000-7000 square feet. (500-700 Square Meters) where people can watch us print, assemble and drive off in our 3D printed vehicles. Our microfactories also contain two types of lab spaces – the first one is the maker lab where customers can co-create designs, concepts, products etc. in conjunction with Local Motors staff. They can also use this space to work on their own projects. Consumers can enjoy the opportunity to talk or work with our engineers in order to co-create new and exciting ideas or products. We also host local design competitions within these spaces – one of the most well-known, recent challenges we hosted was with Airbus, on the Cargo Drone Challenge.

The second lab within the micro factory is the miniaturization lab. Here you will be able to print miniature versions of our cars. You can also bring your children to our micro factory, and together you can print some pretty cool stuff. We even have 3D printing programs for kids aged 3 and under.

Lastly, we have a retail component where we sell co-created products that complement our vehicles as well as branded sourced retail products such as apparel, drinkware, technology items and a host of other safe, smart and sustainable gift items

I like to think of it as the Disneyland of vehicle retailing. At Disneyland, you have the experience of the main venues and then have the opportunity to look through the gift shop to buy a memento of the great experience you’ve just enjoyed. Our micro factories are supposed to be fun as well as educational. You have the opportunity to ask questions about who we are and what we do at Local Motors. And finally, the guest is able to take a piece of that experience home no matter how small that might be.

The ‘Local’ in ‘Local Motors’ means we’re just that. We’re all about local innovation. We accomplish this by combining co-creation within the community together with micro manufacturing. The microfactories allow our customers to come in and experience what Local Motors brand is all about and what makes us different from anyone else in the world producing vehicles – this experience is a key part of what we do.

With a business model that’s such a break from the norm, how important is it for your spaces to educate your customers? Or do the people who walk through the door know all about the concept?

Most people who come through the door need some additional level of education. Generally, we find that people understand 3D printing. However, often times we find that they do not know that large-scale 3D printers exist – printers big enough to print a car.

Education is also needed around who and what Local Motors is, our co-creation platform, and how our microfactories operate. The technology involved is relatively new for all of us, so it is important to spend time making sure that potential consumers are aware of our brand story.

We hired world famous IDEO to help us formalize our branding and retail touchpoints. Two of the most important things they did for us was to help us identify who we are as a company, and also how to clearly communicate our brand story to the public. When we started this interview, I was able to tell you what we did in two sentences. Before IDEO, that may have taken 20 minutes.

Having said that, we do have an extremely active, loyal customer base. I met a 16 or 17 year old young man in Knoxville who’s been following us for the past 6 years. I also recently met a 17 or 18 year old gentleman who could tell you more than I could about the brand and how the cars are made.

Tell me about your Berlin store.

We’re negotiating the space currently – we haven’t executed anything yet. We’re hoping for the space to be live by late summer. The space is going to be located in the city centre, giving us lots of visual impact to familiarize the public with what we do.

Will Local Motors’ cars always be sold direct to customers?

I can’t envision us ever going down the dealer route, as we don’t carry any inventory. At Local Motors, you can come to a microfactory, order a car, and drive it away by the end of the day. You can immerse yourself in the microfactory for the day and watch it be printed.

No one else is doing this – even Tesla, which is seen as an innovator, takes 4-6 weeks to deliver a car. We have no plans to supply dealerships – our process is so rapid, there’s no point.

What percentage of your sales come through physical stores currently?

We have to look at the vehicles we are selling, like the Rally Fighter, rather than the 3D printed cars we’re pre-tailing. Rally Fighter sales usually start with either an online enquiry, or a phone call. Generally, they’ll then come into a microfactory for a test drive and to complete the sale. I’ve never known any customer to walk in off the street to buy one. There’s a mixture of both online and offline engagement.

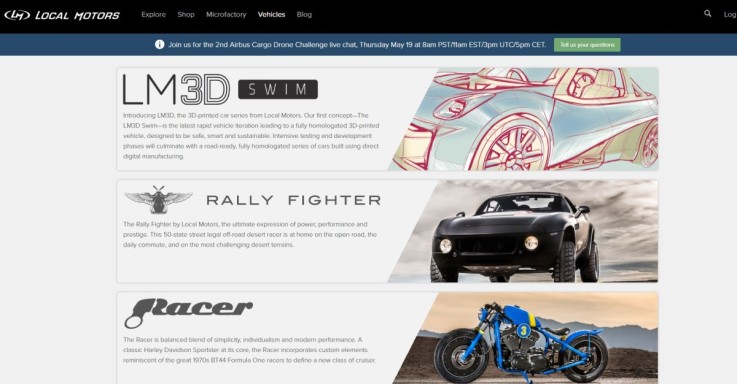

Has Local Motors changed since its launch?

We’re pivoting in quite a major way now. We started with the Rally Fighter, the world’s first co-created vehicle brought to life using our community to design it and our micro factory to build it. Rally Fighters are a limited market – indeed, we only ever wanted it to be a limited market. We always said we would make no more than 2000 Rally Fighters. By limiting production we could keep the resale value of the vehicle at a premium

Now, we’re diving into 3D printing. With 3D printing, we have an opportunity to change the way the world manufactures vehicles. The world still makes cars using the same methods that Henry Ford used 100 years ago.

3D printing has much greater mass appeal. And currently, there’s no competition – no one else is 3D printing cars, let alone designing them with a community. We’re changing the world.

10 years from now, how do you think Local Motors will be different?

The equipment we will use 10 years from now hasn’t even been invented. 10 years ago, it would have seemed crazy to think that we could 3D print cars. I almost cannot begin to imagine what might be possible. It might be feasible for us to print a car in an hour or two hours. Who knows ???

I saw a presentation recently where the presenter said that technology is changing so rapidly, it’s doubling in performance every two years. So as soon as a piece of tech reaches its 2nd birthday, it’s obsolete.

So how has Local Motors developed to ensure that it can adapt to whatever the future brings?

Speed and flexibility plays a huge part in our past success and future sustainability. I have 110% confidence that Local Motors can change and pivot faster than any other vehicle company in the world. We can bring vehicles to market faster than any other company.

We can change the sales floors of our micro factories quickly. We’re currently switching the Rally Fighter floor of our Arizona micro factory into a 3D printing floor for different models – this is pretty quick and painless. It would also be easy for us to expand and add onto our Knoxville micro factory if we wanted to.

Whereas your conventional auto factory can be millions of square feet in size, our microfactories can be 45,000 to 50,000 square feet in size – that’s the size of a Home Depot, or a Lowe’s. It enables us to be very flexible. Other car makers, who produce millions of units every year from a handful of factories, can’t be anywhere near this flexible.

We even make it possible for our customers to stay flexible, too. They can buy one of our cars, drive it for one or two years, before bringing it back to us and trading it in. At that point, we’ll melt it down, and use 80% of the material to build a new car.

I think flexibility comes from the mindset of the people in the business too. The average age of a Local Motors employee is around 30.

You know how people talk about dog years – that 1 year of a dog’s life is the equivalent of 7 human years? I joke that 1 day in Local Motors time is the equivalent of 7 days in a traditional company. And I’ve worked in some fast moving companies. Local Motors is like Star Trek meets Star Wars on steroids.

Do you think people will ever print their own vehicles at home, or on their local high streets, in the way that we get our photos printed today?

I can’t see that happening. The current printing equipment takes up the space of a very large garage, our printing machines cost about $2 million a piece, assembly is needed for parts like the tyres and the steering wheel, and you need a lot of talented people to make it work.

Even in 10 or 20 years, the printers might be a lot faster, more sophisticated and more accessible, but you have to ask yourself why someone would want to print a car themselves, when they could come to us and get exactly the product they want? In time, we will be able to let customers customise their vehicles, with almost infinite variations. We can literally change the body of a car with a file in AutoCAD. If you wanted a car with Mickey Mouse ears, we could make that for you, in a day. There’s no real benefit in going it alone.

How do you think Local Motors will influence conventional car manufacturers’ production/showroom model?

I don’t think the major car manufactures can change that much, so they won’t. They’ve invested a lot in a very fixed way of doing things. They have a huge amount invested in time and resources to get things to market. They invest billions in developing each model, and they have to spend a huge amount on marketing to shift enough units to recoup their initial investment. Dealers have to keep stock, and they have to pay interest on the units they haven’t shifted. The traditional players won’t pivot because it would be too costly.

Our micro factories have around 100 people in them. Our employees can press a button on a 3D printer and walk away, only coming back when the piece is ready. If a bigger manufacturer were to emulate our model, what would they do with their giant factories?

To take a vehicle from concept to customer launch, it can take a traditional car manufacturer 6-8 years. With our co-creation process, we took a 3D printed car from first iteration to a driving stage in 2 months. And the car can be adapted even more after the basic model has been approved – we could adapt a model to make it extremely appropriate to the UK market, where it can get cold and rainy, and adapt it in completely different ways for hot, sunny Arizona. General Motors, Tesla, Hyundai – no other vehicle maker can do that.

As an example, Airbus asked us to help them with its Drone Challenge. They definitely have talent, and they have a lot more money than we do. But they don’t have the platform, or the speed and flexibility that we do. They knew they’d struggle to create that by themselves.

So do you think a lot of the traditional players will go bust?

Well, Baskin Robbins has 31 flavours – not everyone eats chocolate ice cream. Local Motors is one of the 31 flavours – not everyone will want what we have, and some of the traditional players will carry on and do well, but we will find our niche market and succeed.

We can introduce you to interesting people like this and loads of other innovators from London, New York, Berlin and beyond. Find out more here.